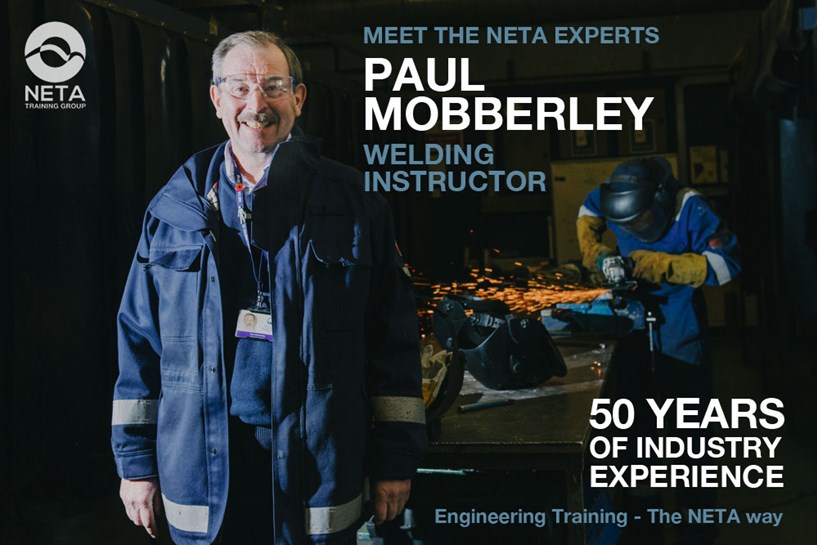

At NETA, we are all about our Instructors and how they pass on their vast knowledge and experience to our customers. This is the first in our series of 'NETA Experts'. Meet Paul Mobberley.

“I’ve always loved welding and I still do. It is a great game. It has given me a good life and you get to meet a lot of characters along the way!”

"If you want a career in welding “you’ve got to love it” says Paul. "The sparks, the heat, wearing a screen all day, it’s not a job for the faint hearted".

A NETA instructor with more than 50 years’ experience, it’s a view Paul shares with those he trains, after all there’s no point in sugaring the pill. Welding is a hands-on trade and that means hard work. But, Paul says, find that you love it and the opportunities are vast. “It’s a good earner too,” he adds. “And it can take you all over the world.”

In his 50 years he has worked across the UK, in Germany and Holland, but it was at Dorman Long Teesside that he first earned his stripes. He would go on to play a part in major projects such as the Thames Barrier gates with Cleveland Bridge and the oil rig jacket known as Graythorp I and II with Laing Offshore.

But reluctant to sing and dance about his working history today, he simply says, “too much to mention,” when asked about the highlights of five decades in trade.

Paul’s career has taken in the petrochemical, offshore oil and gas and module construction industries, all adding to his expertise which he is now more than happy to share.

As an instructor Paul's standards are high, “but they have to be,” he says, after all there are no shortcuts in the real world.

“Being a welder is a good life but a hard life,” he says. His own career hasn’t been without its drama. Paul remembers vowing never again after his first time working offshore. “Nothing can prepare you,” he says. “The wind and the sea, it’s unbelievable.” On that platform he remembers all the anchors snapped when a storm struck, effectively separating the accommodation from the rig. While everyone was airlifted to safety he was one of four welders left behind to weld down the cranes. “I said then I would never work offshore again. But I did!” he says with a shrug.

Today he remains as passionate about his trade as ever and gets the same buzz working alongside those in the industry today.

“I’ve always loved welding and I still do,” he says. “It is a great game. It has given me a good life and you get to meet a lot of characters along the way!”

Worked on: Oil rigs, gas platforms, oil refineries, flood defences, offshore pipework, recovery plants, welding inspection, petrochemical, oil and gas and module construction industries

NETA are able to offer numerous areas of Welder training and testing to all codes, the most common being:

Manual Metal Arc (MMA)

Metal Active/Metal Inert Gas (MIG/MAG)

Tungsten Inert Gas/Tungsten Active Gas (TIG/TAG)

Gas Shielded Flux Cored Arc Welding (FCAW)

Oxy-Acetylene cutting and welding

Safety checks/set-up procedures for all Oxy-Acetylene welding equipment

Advice on which specific coding criteria to test to i.e.:

ASME 1X

BS/EN 15614-1

BS/EN 9606-1

AWS D1.1

Please email us at info@neta.co.uk or phone us on 01642 616936 if you would like more details.